SiPM Mechanics

Here you can find some example of mechanics to assembly SiPMs to be characterized.

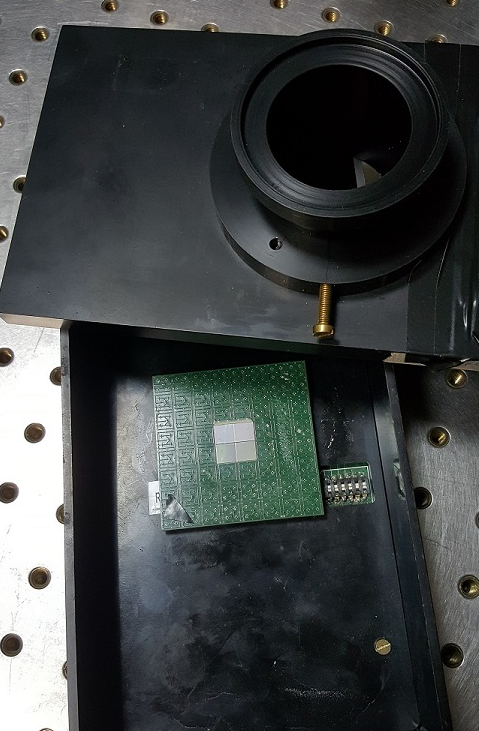

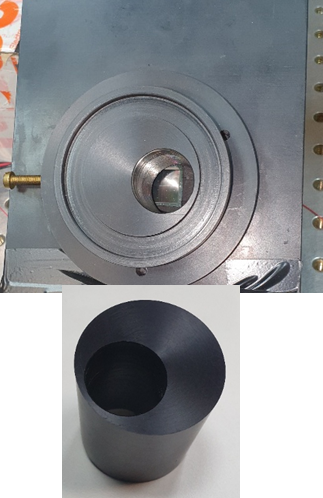

- Light-tight box for simultaneous PDE measurement of SiPMs assembled in a matrix (S14521-7075VN MPPC) for the ASTRI project. The top cover has a mechanical interface that allows the connection to an integrating sphere, the large aperture ensures the illumination of all the array without any vignetting(central panel).

- Light-tight box for PDE characterization of single pixel SiPMs.

- Mechanics to measure the signal response of a detector versus the incidence angle.

|

|

|

Left: SiPM board semi-populated with 4 central SiPMs; the cover has hole capable to be interfaced with an integrating sphere. Centre: detail of the hole with a large aperture to not vignetting the central pixels. Right: cover that can mount an eccentric able to select one of the four pixels and reproduce the same optical phat of the NIST photodiode used as reference detector.

The mechanical set-up showed in this above picture can be easily interfaced to an integrating sphere and can guarantee a dark condition inside the box.

|

|

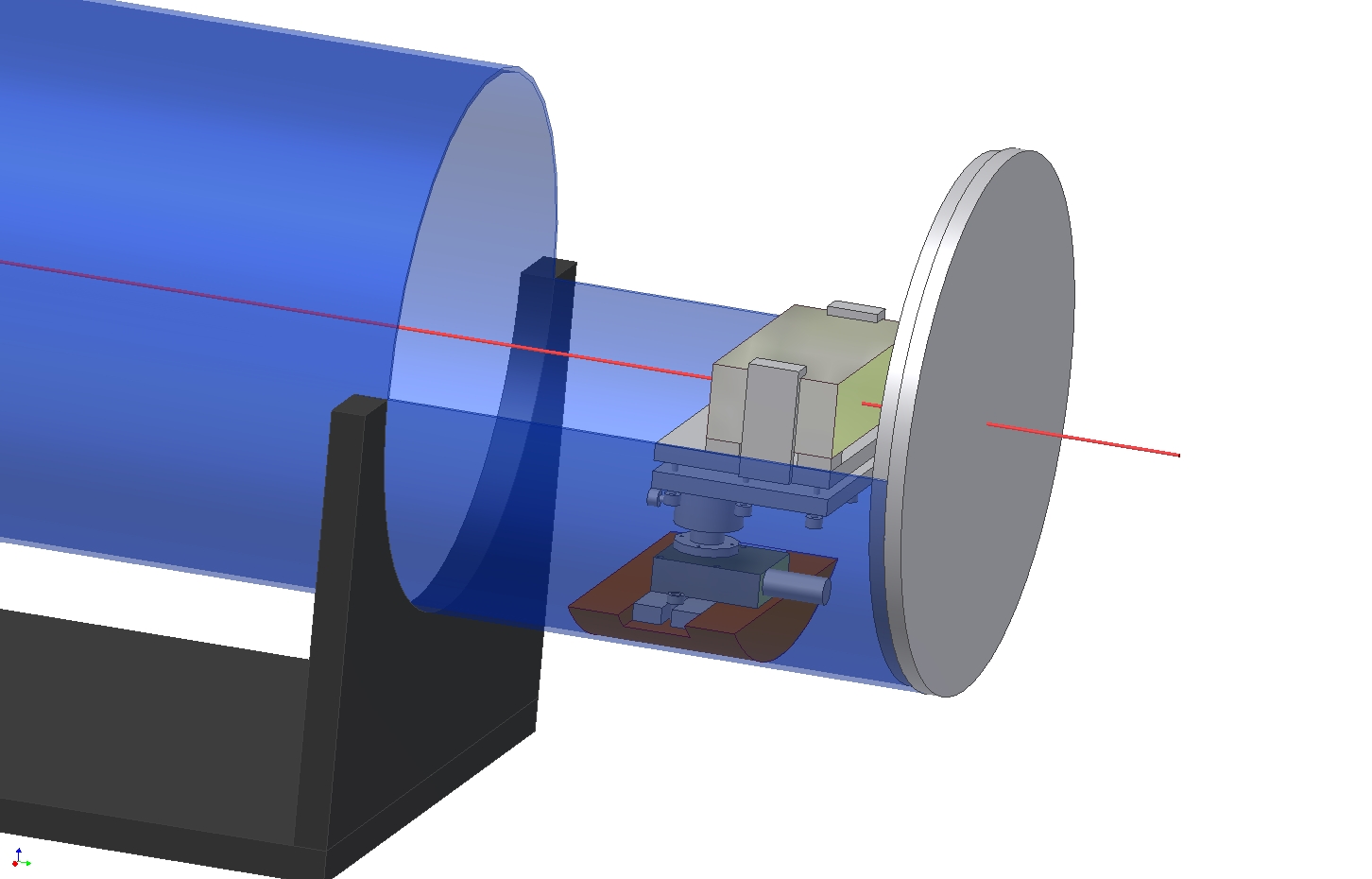

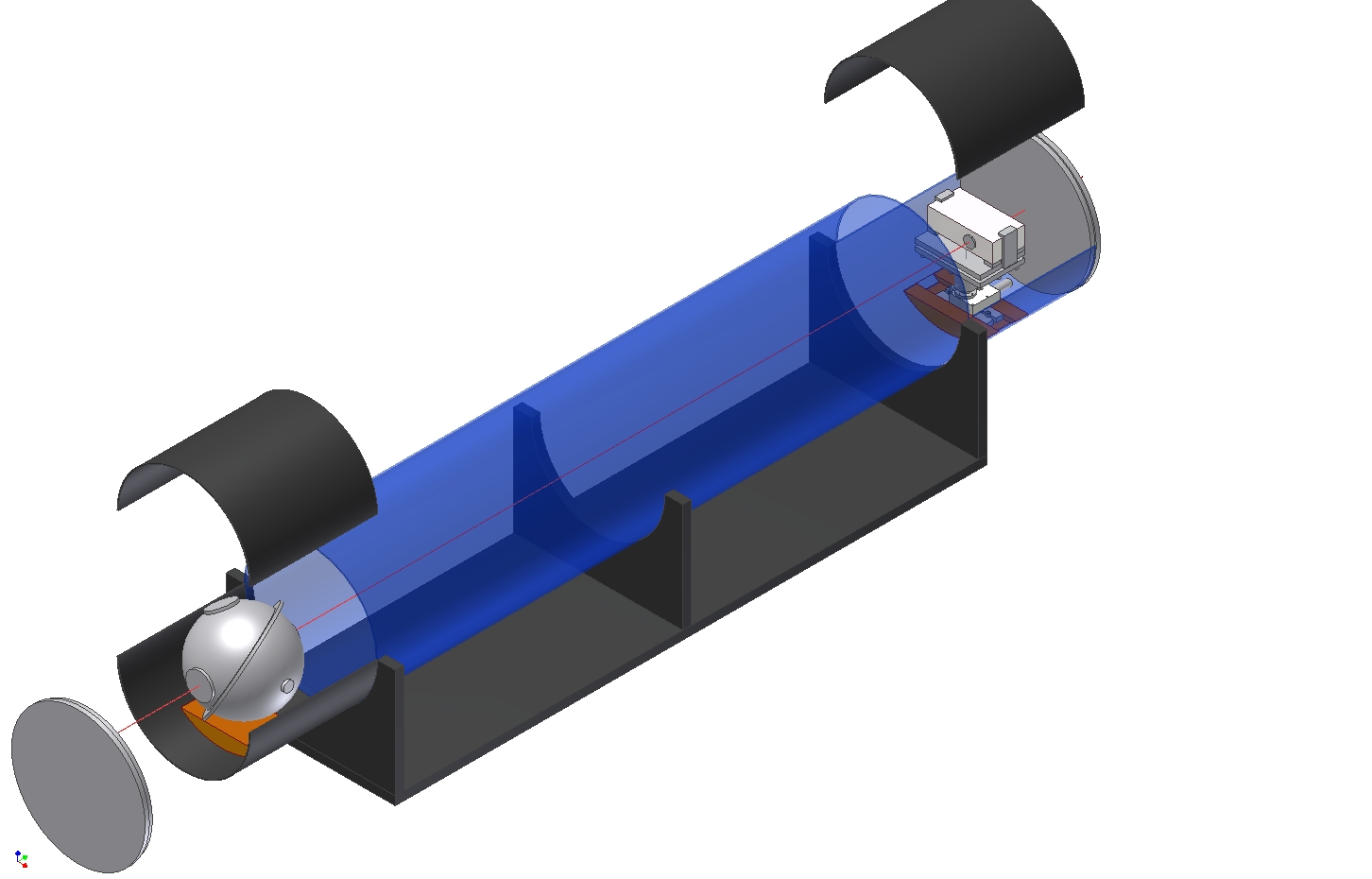

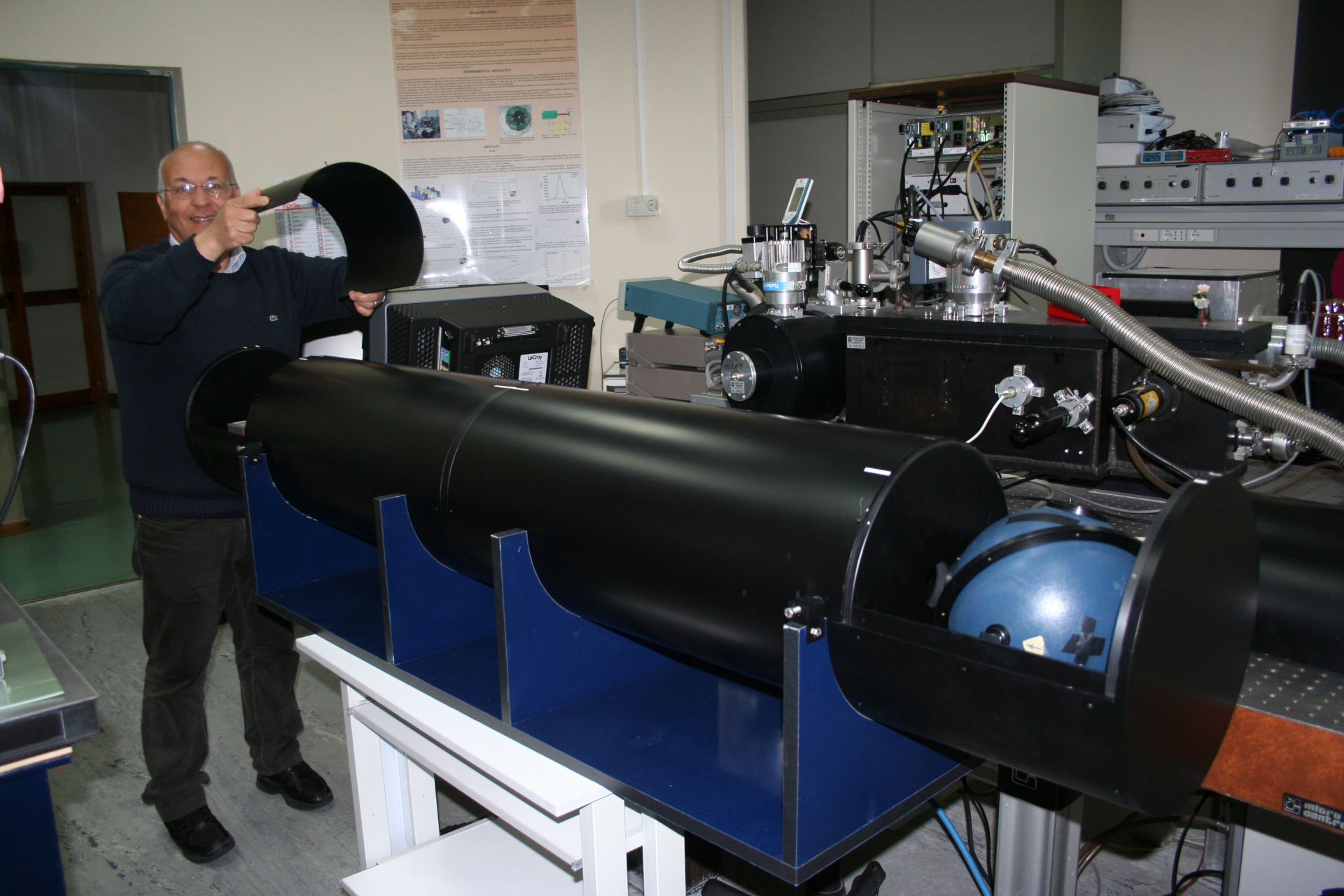

The set-up consists of a power and amplification (PSAU) system manufactured by CAEN adapted for any type of SiPM sensor, a light source with a high degree of uniformity and a 2-m long PVC cylindrical light-tight enclosure.

The source is a green LED (568-nm wavelength), feeding a Labsphere standard integrating sphere (mod. IS-080,8-in. diameter), that gives a uniform irradiance at the output port.

To obtain a collimated beam we introduced two diaphragms of 5 cm diameter along the tube.

Taking into account the presence of these diaphragms, the length of the tube and the small MPPC dimensions, the beam divergence is lower than 1°, and this assures a very high accuracy.

The rotary stage (OWIS DMT40-D20-HSM) can be controlled via computer, and permits a positional accuracy of 1/10 of a degree(from the manufacturer datasheet).The correct positioning of the SiPM with respect to the axis of rotation is assured by the presence of three linear stages that allow the translation of the SiPM itself: a laser beam is used to produce a spot on the surface of the detector and the linear stages are moved, checking that in rotating the system the spot does not move.

A fan mounted behind the PSAU-SiPM system ensures the re-moval/dispersal of the excess heat generated by the PSAU electronics.